Cracking the Code: Using Code Aster for Creep and Fatigue Assessment in API 579-1/ASME FFS

The oil and gas, petrochemical, and power generation industries heavily rely on aging infrastructure operating under demanding conditions. Ensuring the integrity of these assets is paramount, and API 579-1/ASME Fitness-For-Service (FFS) provides a robust framework for evaluating the structural integrity of in-service components with flaws.

Finite Element Analysis (FEA) is an indispensable tool in the FFS assessment process, allowing engineers to predict stress distributions and behavior under complex loading scenarios. While commercial FEA packages abound, Code Aster, a powerful and free open-source solver, offers a compelling alternative. This blog post explores how you can leverage Code Aster for creep and fatigue assessment in accordance with API 579-1/ASME FFS.

Why Code Aster for FFS?

- Cost-Effectiveness: Being open-source, Code Aster eliminates licensing fees, making it accessible to a wider range of users.

- Flexibility and Customization: Its open architecture allows for extensive customization and integration with other tools.

- Comprehensive Material Models: Code Aster boasts a library of material models suitable for simulating the behavior of various materials under creep and fatigue conditions.

- Active Community Support: A vibrant community provides support, documentation, and examples, facilitating learning and troubleshooting.

Key Steps in Creep and Fatigue Assessment with Code Aster

Let’s break down the typical workflow for performing creep and fatigue assessments using Code Aster, referencing relevant sections within API 579-1/ASME FFS:

1. Model Creation and Meshing:

- Geometry: Accurate geometric representation of the component is crucial. You can import CAD models from various formats or create them directly within a pre-processor like Salome-Meca (which integrates seamlessly with Code Aster).

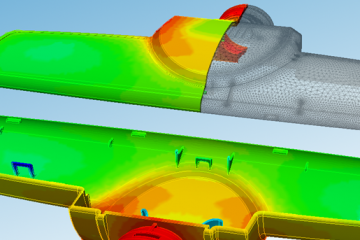

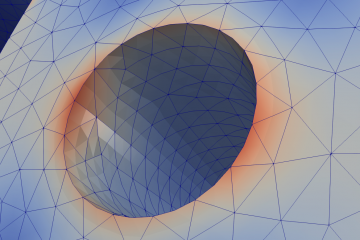

- Meshing: Generate a high-quality mesh. Fine meshes are essential in regions of stress concentrations (e.g., near welds, cracks) to accurately capture stress gradients. Consider using adaptive meshing techniques to refine the mesh automatically in critical areas. API 579-1/ASME FFS Section 4 and Appendix A address mesh requirements and considerations.

2. Material Properties Definition:

- Creep Properties: Define the material’s creep behavior using appropriate creep models available in Code Aster (e.g., Norton’s law, Garofalo model). Ensure accurate creep data is obtained for the operating temperature range. API 579-1/ASME FFS Section 9 covers creep behavior and required material properties.

- Fatigue Properties: Specify the material’s fatigue properties, including S-N curves (stress vs. number of cycles) and fatigue crack growth parameters (da/dN vs. ΔK). Material data should be representative of the specific material and environment. API 579-1/ASME FFS Section 10 details fatigue assessment procedures.

3. Loading and Boundary Conditions:

- Load Cases: Define all relevant load cases, including pressure, temperature, mechanical loads, and cyclic loads. Accurately represent the operational loading profile.

- Boundary Conditions: Apply appropriate boundary conditions to constrain the model and simulate the component’s support conditions.

4. Analysis Setup in Code Aster:

- Static Analysis (for Creep): Perform a static analysis with the creep material model activated. Define the analysis duration to simulate the time-dependent creep deformation. Use the

THER_NON_LINEcommand to perform non-linear thermal-mechanical analysis. - Cyclic Loading Analysis (for Fatigue): Apply cyclic loading using a step-by-step analysis. You can use harmonic analysis or transient analysis to simulate the cyclic behavior. Implement rainflow counting algorithms (often done post-processing) to determine the number of cycles at different stress ranges.

- Crack Growth Analysis: Utilize Code Aster’s fracture mechanics capabilities to simulate crack growth under cyclic loading. This involves defining the initial crack geometry, specifying the fatigue crack growth model, and running the analysis to predict crack propagation. This aligns with API 579-1/ASME FFS Section 9 and Appendix C.

5. Post-Processing and Results Interpretation:

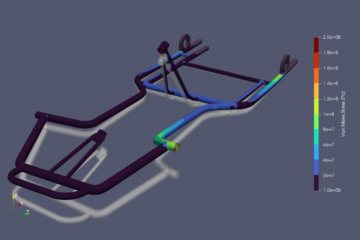

- Stress Analysis: Examine the stress distribution in the component. Identify regions of high stress concentration.

- Creep Strain Calculation: Calculate creep strain accumulation over time. Compare the calculated creep strain to allowable limits specified in API 579-1/ASME FFS.

- Fatigue Life Prediction: Based on the stress ranges and cycle counts obtained from the cyclic analysis, calculate the fatigue life using S-N curves or fatigue crack growth analysis. Compare the predicted life to the design life or remaining life requirements.

- Fitness-For-Service Assessment: Compare the analysis results to the acceptance criteria outlined in API 579-1/ASME FFS. Determine if the component is fit for continued service.

Example Code Snippet (Simplified Creep Analysis):

# This is a highly simplified example and requires significant expansion for a real-world analysis

from aster.core import AsterStudy

ast_study = AsterStudy()

# ... (Code for defining geometry, mesh, material properties, boundary conditions, loading) ...

# Define creep material model (Norton's Law)

mat = ast_study.material(name='SteelCreep',

model='VISCO_NORTON',

A=1.0E-15, # Creep constant

N=5.0, # Creep exponent

Q=100000.0 ) # Activation energy (adjust as needed)

# Define static mechanical analysis with creep

ana = ast_study.static(name='CreepAnalysis',

material=mat,

load=load,

boundary_condition=bcs,

duration=1000.0, # Analysis duration in hours

time_step=10.0) # Time step size

# Solve the analysis

ast_study.solve(ana)

# ... (Code for post-processing and results extraction) ...Challenges and Considerations:

- Material Data: Accurate material data is crucial for reliable results. Gathering sufficient creep and fatigue data can be challenging and expensive.

- Modeling Complexity: Accurately modeling complex geometries, boundary conditions, and material behavior can be demanding.

- Computational Resources: Creep and fatigue analysis, especially crack growth simulations, can be computationally intensive.

- Validation and Verification: Validate your FEA model against experimental data or analytical solutions to ensure accuracy and reliability.

Conclusion:

Code Aster offers a powerful and cost-effective solution for performing creep and fatigue assessments in accordance with API 579-1/ASME FFS. While it requires a steeper learning curve than commercial software, its flexibility, customization options, and open-source nature make it a compelling choice for engineers seeking to ensure the integrity of aging infrastructure. By following the guidelines outlined in API 579-1/ASME FFS and mastering Code Aster’s capabilities, you can confidently assess the fitness-for-service of critical components and contribute to safer and more reliable operations. Remember to always validate your models and results. Happy analyzing!

CloudHPC is a HPC provider to run engineering simulations on the cloud. CloudHPC provides from 1 to 224 vCPUs for each process in several configuration of HPC infrastructure - both multi-thread and multi-core. Current software ranges includes several CAE, CFD, FEA, FEM software among which OpenFOAM, FDS, Blender and several others.

New users benefit of a FREE trial of 300 vCPU/Hours to be used on the platform in order to test the platform, all each features and verify if it is suitable for their needs

0 Comments