Enhancing Fan Efficiency: ErP efficiency Regulation and Utilizing CFD Software

In today’s world, where energy efficiency and sustainability are becoming increasingly important, regulations governing the energy performance of appliances play a crucial role. One such regulation impacting the fan industry is the Energy-related Products (ErP) Directive in the European Union. This directive aims to improve the energy efficiency of products, including fans, and reduce their environmental impact. In this blog post, we’ll explore what the ErP regulation entails for fans and how Computational Fluid Dynamics (CFD) software can be leveraged to enhance fan efficiency.

Understanding ErP efficiency Regulation

The ERP efficiency Directive, also known as Directive 2009/125/EC, sets minimum energy efficiency standards for energy-related products sold within the EU. It covers various product categories, including fans, with the goal of reducing energy consumption and greenhouse gas emissions. For fans, the regulation focuses on improving efficiency by establishing requirements for energy consumption, power input, and performance metrics.

Key Components of ErP Regulation for Fans

- Minimum Efficiency Requirements: The ErP regulation sets minimum efficiency requirements for fans based on their intended use and performance characteristics. These requirements aim to ensure that only energy-efficient fans are available on the market, driving the adoption of sustainable technologies.

- Energy Efficiency Classes: Fans are classified into different energy efficiency classes based on their performance and energy consumption. This classification helps consumers make informed choices by providing clear indicators of a fan’s efficiency level.

- Labeling Requirements: To promote transparency and consumer awareness, fans covered by the ErP regulation must display energy efficiency labels indicating their class and performance parameters. This allows consumers to compare the energy efficiency of different fan models easily.

Improving Fan Efficiency with CFD Software

Computational Fluid Dynamics (CFD) software offers a powerful tool for optimizing the design and performance of fans, thereby enhancing their efficiency. Here’s how CFD software can contribute to improving fan efficiency:

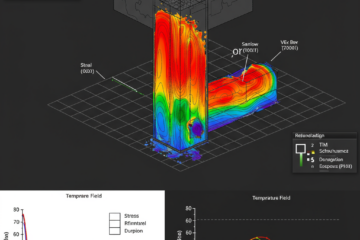

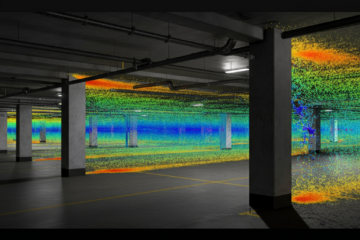

- Simulation and Analysis: CFD software enables engineers to simulate airflow patterns, pressure distribution, and thermal behavior within fan systems. By analyzing these simulations, designers can identify inefficiencies, such as flow separation, recirculation, or pressure losses, and make design modifications to improve performance.

- Optimization of Fan Geometry: CFD simulations allow for the optimization of fan geometry, including blade shape, angle, and curvature, to maximize airflow efficiency and minimize energy consumption. Through iterative simulations, engineers can fine-tune the design parameters to achieve optimal performance.

- Validation of Design Modifications: CFD software enables virtual testing of design modifications before physical prototyping, reducing time and costs associated with experimental testing. Engineers can validate the effectiveness of design changes in improving fan efficiency and performance through accurate simulations.

- Evaluation of System Integration: CFD simulations can assess the interaction between fans and the surrounding system components, such as ducts, filters, and heat exchangers. By optimizing the integration of fans within the overall system, engineers can minimize energy losses and enhance overall system efficiency.

Conclusion

The ErP regulation presents a significant opportunity for the fan industry to prioritize energy efficiency and sustainability. By complying with minimum efficiency requirements and leveraging technologies like CFD software, manufacturers can improve the design and performance of fans, ultimately reducing energy consumption and environmental impact. As organizations embrace innovation and strive for greater efficiency, CFD software remains a valuable tool for optimizing fan systems and advancing towards a more sustainable future.

CloudHPC is a HPC provider to run engineering simulations on the cloud. CloudHPC provides from 1 to 224 vCPUs for each process in several configuration of HPC infrastructure - both multi-thread and multi-core. Current software ranges includes several CAE, CFD, FEA, FEM software among which OpenFOAM, FDS, Blender and several others.

New users benefit of a FREE trial of 300 vCPU/Hours to be used on the platform in order to test the platform, all each features and verify if it is suitable for their needs

0 Comments