🔥 Beyond the Standard: ISO 834 Curve vs. Real Fire Simulation in Structural Validation

When designing buildings, ensuring the structure can withstand a fire for a specified duration is paramount. This validation often hinges on understanding how the surrounding air temperature will evolve over time—a process often simplified by standard temperature curves.

The most globally recognized standard for this is the ISO 834 standard fire curve. However, in modern fire safety engineering, a more accurate, performance-based approach is gaining traction: using the real fire curve obtained from a computational fluid dynamics (CFD) analysis, typically performed using Fire Dynamics Simulator (FDS).

The Industry Staple: The ISO 834 Standard Fire Curve

The ISO 834 standard fire curve is a conventional, time-temperature curve used worldwide for classifying the fire resistance of building elements and materials (walls, columns, floors, etc.).

1. What is it?

The ISO 834 curve, sometimes referred to as the standard cellulosic curve, is an empirical model that describes the temperature increase in a furnace during a standardized fire resistance test.

2. The Equation

The temperature θ (in °C) as a function of time t (in minutes) is given by the formula:

θ(t) = 345 log10(8t + 1) + 20

3. Why is it Used?

- Simplicity and Consistency: It provides a uniform, standardized way to test and compare different building elements globally.

- Safety Margin: It represents a worst-case scenario for a well-ventilated compartment fire where the fire load is entirely cellulosic (like wood or paper). This provides an inherent, albeit non-specific, safety margin for typical residential and office structures.

- Regulatory Compliance: Many building codes and regulations require testing to be carried out against this standard curve.

4. The Limitation

The ISO 834 curve assumes a fully-developed fire in a compartment where the fire grows indefinitely according to the curve. It doesn’t account for crucial real-world factors like:

- The actual size, type, and location of the fire load.

- The compartment’s ventilation (window/door openings).

- The thermal properties of the surrounding walls and ceiling.

- The decay phase (when the fire starts to die out).

The Performance-Based Alternative: The Real Fire Curve via FDS

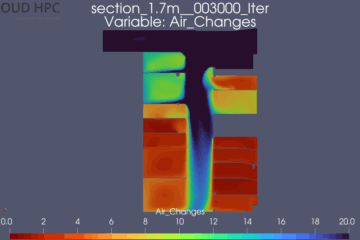

Fire safety engineering (FSE) is a modern approach that moves beyond prescriptive standards to analyze the specific fire scenario in a building. The key tool for obtaining an accurate temperature profile is Computational Fluid Dynamics (CFD), with Fire Dynamics Simulator (FDS) being the most widely used software.

1. What is FDS?

FDS is a scientific software tool that models fire-driven fluid flow. It solves the conservation equations for mass, momentum, and energy, with an emphasis on low-speed, thermal-driven flow and heat transfer. In simpler terms, it creates a virtual fire inside a virtual room.

2. The Real Fire Curve Procedure

- Define the Scenario: Engineers define the exact fire load (e.g., furniture, storage), the ignition location, and the precise geometry and ventilation of the fire compartment.

- FDS Simulation: FDS runs the simulation, calculating the gas temperatures throughout the room over time.

- Obtain the Curve: The temperature history at the critical structural element (e.g., a column) is extracted. This is the real fire curve (or design fire curve). This curve often shows a rapid rise, a peak, and then a cooling phase—a critical difference from the standard curve.

- Structural Validation: This more realistic curve is then used as the thermal input for the structural validation (e.g., in a Finite Element Analysis (FEA) model) to determine the actual time the structure maintains its stability.

🆚 Head-to-Head Comparison

| Feature | ISO 834 Standard Curve | Real Fire Curve (via FDS) |

| Basis | Empirical test data (Furnace) | Physics-based CFD simulation |

| Scenario | Generic, well-ventilated “standard” fire | Specific to the actual room/building |

| Cooling Phase | Non-existent (continues rising/leveling) | Included (shows the fire dying out) |

| Accuracy | Lower (Conservative, but not precise) | Higher (Specific to the design) |

| Design Impact | Often leads to oversized fire protection (e.g., thicker concrete cover, more intumescent coating) | Allows for optimized fire protection, potentially reducing material costs and construction time |

| Complexity | Simple, ready-to-use | Requires specialized FSE expertise and significant computational time |

🔑 The Takeaway for Structural Validation

The choice between the two methods comes down to project requirements and risk tolerance:

- Use ISO 834 when: Compliance with minimum code is sufficient, the structure is simple, or a conservative, worst-case approach is desired without the cost of a detailed analysis.

- Use a Real Fire Curve (FDS) when:

- Cost/Space Optimization is critical (e.g., a massive project where reducing the fire protection thickness saves significant money and gains usable floor space).

- Complex/Atypical Structures are involved (e.g., very tall buildings, unique geometry, or structures with atypical ventilation).

- The fire scenario is known to be ventilation-controlled or involves specific, non-cellulosic fire loads, where the ISO 834 curve would be overly conservative or simply inaccurate.

Ultimately, while the ISO 834 curve remains the essential benchmark for fire resistance, utilizing the real fire curve through FDS analysis offers a powerful, performance-based method that enables safer, more efficient, and often more cost-effective structural design.

📝 Disclaimer

Important Notice Regarding Fire Safety Engineering and Structural Design

The information provided in this blog post regarding the ISO 834 standard fire curve and the use of the Fire Dynamics Simulator (FDS) for obtaining a real fire curve is for general informational and educational purposes only.

This content is not a substitute for professional engineering advice.

- Consult Professionals: Structural validation, fire resistance classification, and the design of fire protection measures are complex processes that must be performed by qualified, licensed professional fire safety engineers and structural engineers familiar with the local building codes, regulations, and project-specific risks.

- Context Matters: The ISO 834 curve is a prescriptive standard, while FDS-derived real fire curves are performance-based and highly dependent on the specific inputs and assumptions made during the simulation. Any error in the FDS model inputs (e.g., ventilation, fire load, material properties) can lead to significant inaccuracies in the resulting temperature curve and, consequently, an inadequate structural design.

- Regulatory Compliance: Always ensure that your chosen method for structural fire resistance validation (whether standard or performance-based) is explicitly permitted and approved by the relevant Authority Having Jurisdiction (AHJ) for your project location.

The author and publisher of this post assume no liability for any actions taken or not taken based on the content of this article. Your use of the information contained herein is solely at your own risk.

CloudHPC is a HPC provider to run engineering simulations on the cloud. CloudHPC provides from 1 to 224 vCPUs for each process in several configuration of HPC infrastructure - both multi-thread and multi-core. Current software ranges includes several CAE, CFD, FEA, FEM software among which OpenFOAM, FDS, Blender and several others.

New users benefit of a FREE trial of 300 vCPU/Hours to be used on the platform in order to test the platform, all each features and verify if it is suitable for their needs