🚀 Revolutionizing Turbofan Design: CFD and AI Achieve Unprecedented Efficiency

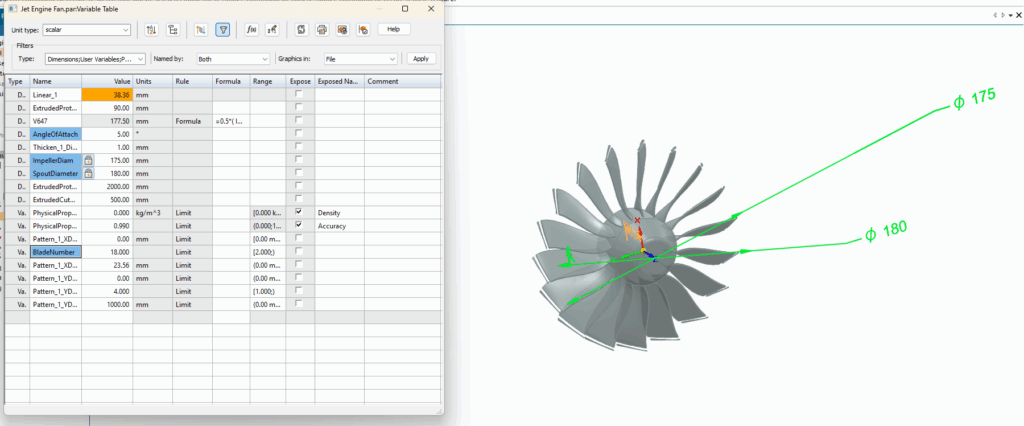

The path to optimized turbomachinery, like the turbofan impeller shown, traditionally involves computationally expensive simulations. However, a recent project by CFD FEA SERVICE SRL demonstrates how integrating Computational Fluid Dynamics (CFD) with Machine Learning (ML) AI can dramatically accelerate the design process and yield superior results.

🛠️ The Design of Experiments (DOE) Foundation

The project began with a parametric CAD model of the turbofan impeller, allowing for systematic variation of key geometric features . A Design of Experiments (DOE) was then conducted, generating 34 unique geometric variations.

Each of these configurations was subjected to a full CFD analysis, a crucial step for understanding fluid flow and performance metrics like:

- Total Pressure (Ptotal): Visualized in the simulation result , this pressure map is vital for assessing the energy imparted to the fluid.

- Absorbed Power (P): The mechanical power required to drive the impeller.

- Static Efficiency (ηstatic): The key performance metric, calculated as the ratio of useful power output to the absorbed power input.

The initial CFD simulations established a baseline, identifying the best-performing geometry among the 34 tested configurations.

🧠 AI Takes the Wheel: Supercharging Optimization

While 34 simulations provided a solid start, exploring the entire design space with CFD alone would be prohibitively time-consuming. This is where the AI tool, developed by CFD FEA SERVICE SRL, came into play.

The results (power and efficiency data) from the 34 CFD simulations were used to train a Machine Learning model. This model learned the complex, non-linear relationship between the impeller’s geometric parameters and its resulting performance.

Armed with this trained AI, the engineers explored a much broader design space, submitting 240 additional, untested geometric configurations to the ML tool for rapid performance prediction.

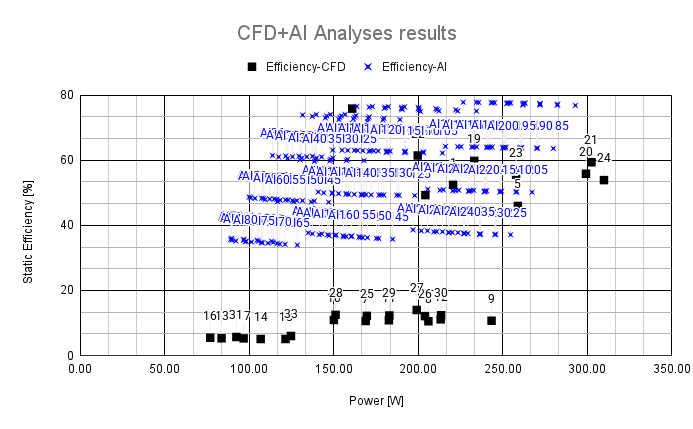

The above image shows in black the tested geometries in a chart where lower axis is the absorbed power and the vertical one is the static efficiency. Blue cross are the data generated using AI.

📈 The Breakthrough: AI-Driven Efficiency Gain

The “CFD+AI Analyses results” plot vividly illustrates the power of this integrated approach:

- Black Squares (■): Represent the results of the initial 34 CFD simulations.

- Blue Crosses (×): Represent the 240 configurations predicted by the AI model.

Crucially, the AI predictions extended well beyond the best efficiency achieved by the initial CFD set. The AI tool successfully identified a new, highly optimized configuration that was predicted to be about 15% more efficient than the best geometry from the initial 34 CFD runs.

✅ Validation: Closing the Loop with CFD

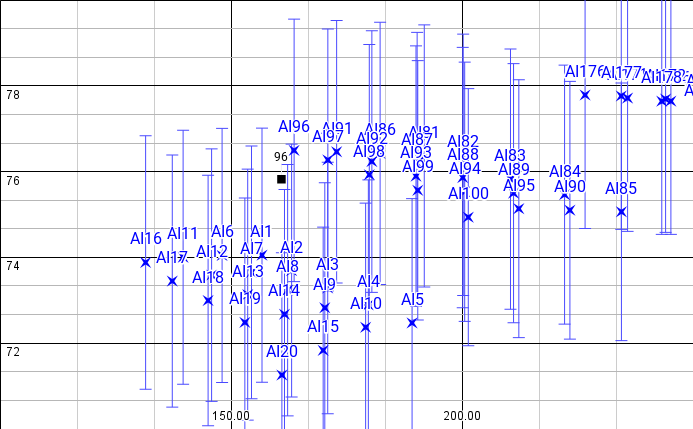

The true test of the AI’s predictive power was the final validation step:

- The AI-optimized geometry was taken back to the CFD environment and simulated.

- The results from the validation CFD simulation closely matched the high-efficiency prediction made by the AI.

A closser look at the results showed how AI96 (results produced by AI for the geometry ID number 96) are less than 2% away from the same geometry simulated using CFD (black square marked with 96 in this graph).

This successful validation confirms that the combined CFD-AI methodology is a powerful and reliable way to discover high-performance designs that might be missed in a purely simulation-based DOE. This approach drastically reduces the time and cost of the design cycle while achieving superior product performance.

Would you like to explore how this CFD-AI optimization process could be applied to a different turbomachinery component, such as a centrifugal pump or a turbine blade? Register now to https://cloudhpc.cloud

CloudHPC is a HPC provider to run engineering simulations on the cloud. CloudHPC provides from 1 to 224 vCPUs for each process in several configuration of HPC infrastructure - both multi-thread and multi-core. Current software ranges includes several CAE, CFD, FEA, FEM software among which OpenFOAM, FDS, Blender and several others.

New users benefit of a FREE trial of 300 vCPU/Hours to be used on the platform in order to test the platform, all each features and verify if it is suitable for their needs