The Challenge: From CFD to HPC

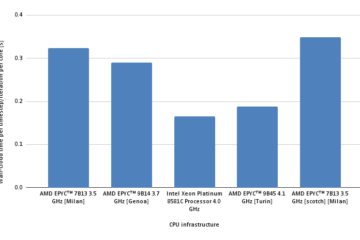

Modern Computational Fluid Dynamics (CFD) algorithms are capable of running transient analyses with advanced turbulence modeling, making them popular for designing turbomachinery. However, achieving a higher level of accuracy and running multiple analyses simultaneously for optimization requires a complete High-Performance Computing (HPC) system. The challenge is compounded by the continuous and rapid evolution of hardware, with new processors, hybrid CPU-GPU solvers, and methodologies constantly modifying HPC requirements.

HPC on the Cloud: A Solution

While some believe in “democratizing” CFD by simplifying software to make it available to everyone, this approach has limitations because CFD settings, mesh definition, and result interpretation still demand significant expertise. Instead, the focus should be on “HPC democratization”. HPC systems require IT skills, not CFD skills, so by making HPC more accessible, users can concentrate on their CFD problems.

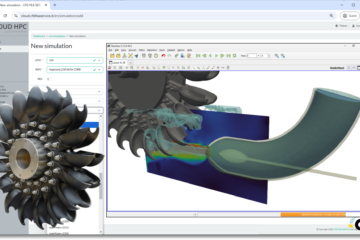

Cloud HPC offers a solution by providing on-demand access to the necessary hardware resources. This approach allows users to manage a cluster from their personal computer without needing to install anything. The service is up-to-date with the latest hardware and software, and can handle up to 112 cores per job and 40 simultaneous jobs.

Case Study: Fan Impeller Optimization

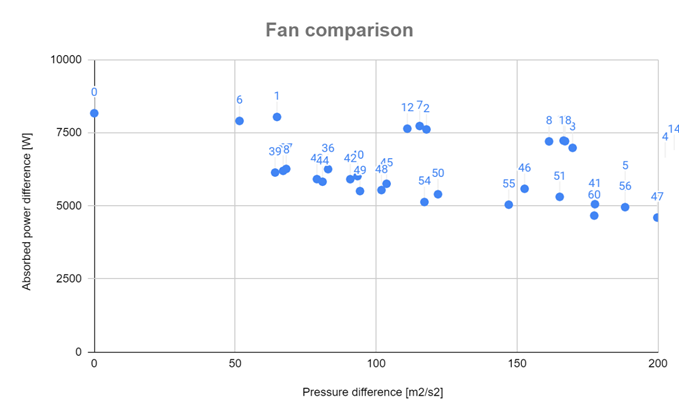

A real-world application of Cloud HPC technology involved the optimization of a fan impeller. The project aimed to improve fan efficiency and pressure while reducing power consumption.

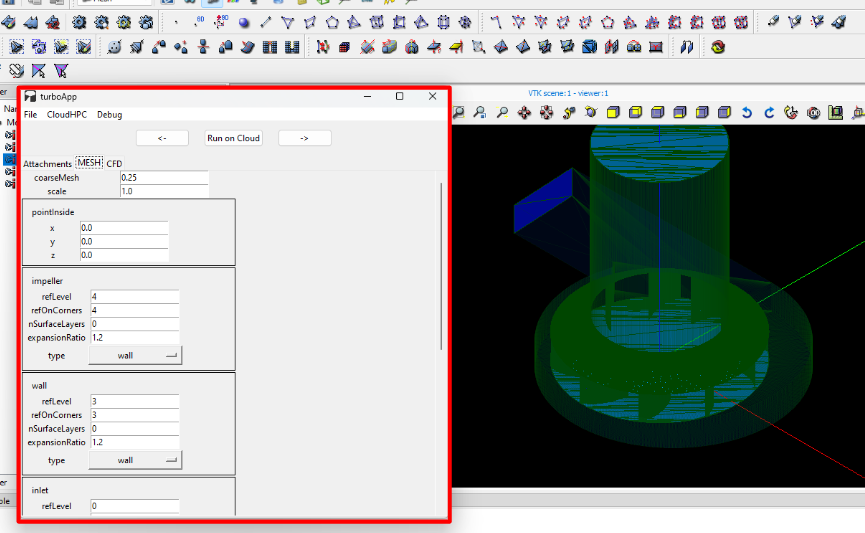

The project utilized a parametric CAD model of the impeller with 12 parameters to define the geometry. The workflow, managed by the dedicated “turboApp,” involved an automatic process from the initial STEP/STL file to a CSV file with the integral results of the CFD analyses.

The CFD analysis was performed using OpenFOAM v9 with specific settings for meshing and turbulence modeling, including the k-Omega SST model. The CFD simulations were run on a Cloud HPC service, which enabled the team to run multiple analyses simultaneously using remote hardware resources.

Results and Conclusions

The project involved a total of 107 models with two conditions each, resulting in 214 CFD analyses. Each individual analysis took approximately 2 hours using 48 cores on an AMD EPYC ROME 3.1 GHz processor. By running up to 40 analyses simultaneously on the cloud, the total computational time for all 214 analyses was reduced to about 10 hours. This represents a significant reduction in total computational time compared to a serial CFD scenario on a single workstation.

The optimization successfully achieved its goals:

- The input power in Point 1 was reduced from 13.8 kW to 11.8 kW.

- The input power in Point 2 was reduced from 21.5 kW to 16.8 kW.

- The pressure tolerance was maintained within 10% of the requested pressure.

- The absorbed power difference was reduced by more than 2.5 kW compared to the original impeller.

- The total design analysis time was reduced thanks to automation.

- The project demonstrated the effective availability of hardware resources provided by Cloud HPC for performing Design of Experiments (DOE).

The total cost for running 214 simulations, each with 48 cores for 2 hours, was approximately €870, including a 15% discount for high usage. This case study highlights the benefits of using cloud-based HPC for complex engineering simulations and optimizations.

CloudHPC is a HPC provider to run engineering simulations on the cloud. CloudHPC provides from 1 to 224 vCPUs for each process in several configuration of HPC infrastructure - both multi-thread and multi-core. Current software ranges includes several CAE, CFD, FEA, FEM software among which OpenFOAM, FDS, Blender and several others.

New users benefit of a FREE trial of 300 vCPU/Hours to be used on the platform in order to test the platform, all each features and verify if it is suitable for their needs